Equipment with an integrated SCR catalyst to comply with the German 44. BImSchV

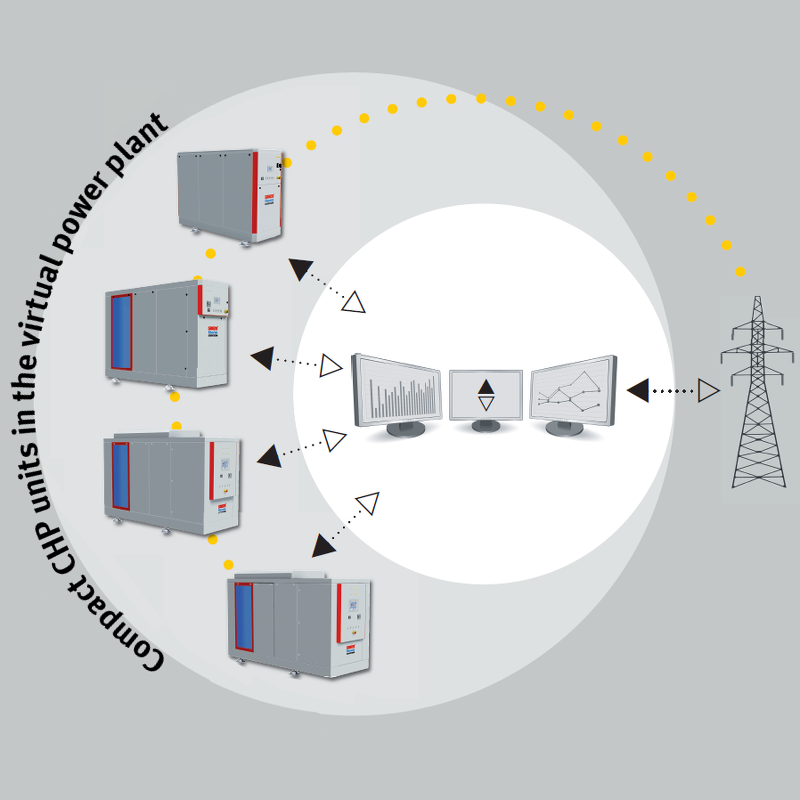

Compact CHP unit with integrated SCR system consisting of urea injector, mixer section and SCR catalyst.

Our compact CHP units with turbo engine and oxidation catalyst can be equipped with an SCR catalyst integrated inside the sound absorbing case. The delivery scope then also contains a urea supply tank with high-pressure pump and emissions controller to be placed next to or behind the CHP unit. On customer side only a urea supply tank with pump is necessary. As an alternative to this space-saving integrated solution we can also deliver an external SCR catalyst which can also be retrofitted after the initial commissioning of the CHP scheme.

With both solutions, all emission values are kept below the relevant limit values of the 44th BImSchV (BundesImmissionsSchutzVerordnung, meaning Federal Emission Control Act) as well as the NOx limit value of 0.1 g/Nm³ valid starting 2025 for natural gas powered CHP units with 1 MW or more gas input. The NOx Values are measured continuously and logged every 10 seconds in the CHP control unit. The day’s average values can be, as prescribed in 44th BImSch, transmitted to the plant operator as well as to the authorities via our RemoteManager system. Further details about emissions reduction can be found here.